ASME B16.3-2006 pdf download

ASME B16.3-2006 pdf download.Malleable lron Threaded Fittings.

Use of a pressure rating at a material temperature other than that of the contained fluid is the responsibility of the user and subject to the requirements of any applicable code.

(d) Class 300 street elbows are not recommended for pressures above 600 psi.

3 SIZE

3.1 Nominal Pipe Size

As applied in this Standard, the use of the phrase “nominal pipe size” or the designation NPS followed by a dimensionless number is for the purpose of identifying the end connection of fittings. The number is not necessarily the same as the fitting inside diameter.

3.2 Reducing Fittings

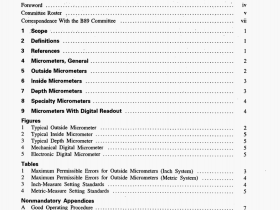

For reducing tees, crosses, and Y-branches (laterals), the size of the largest run opening shall be given first, followed by the size of the opening at the opposite end of the run. Where the fitting is a tee or Y-branch (lateral), the size of the outlet is given last. Where the fitting is a cross, the largest side-outlet opening is the third dimension given, followed by the opposite opening. The straight-line sketches of Fig. 1 illustrate how the reducing fittings are read.

4 MARKING

4.1 Class 150 Fittings

Each Class 150 fitting shall be marked for identification with the manufacturer’s name or trademark.

4.2 CLass 300 Fittings C

Each Class 300 fitting shall be marked for identification with

(a) the manufacturer’s name or trademark

(b) the numerals “300”

(c.) the letters “Ml” to designate malleable iron

(d) the size

(e) other markings as permitted by MSS SP-25

5 MATERIAL

5.1 Malleable Iron

The chemical and physical properties of the castings shall be in accordance with ASTM A 197. The manufacturer shall be prepared to certify that the product has been so produced.

5.2 Steel

Class 150 couplings and caps in NPS 1/s, 1/4, and 3K may be made from steel rod or bar with a minimum yield strength of 30 ksi at the manufacturer’s option.

(a) Metal Thickness Tolerances. Metal thickness at no point in the castings shall be less than 90% of the value given in the tables.

(b) Ccii fer-fo-End Tolera iices. Permitted tolerances on the center-to-end dimensions of the fittings are shown in Tables 2 and 1-2. Tolerances for end-to-end dimensions and lengths of couplings and reducers shall he twice those given. The largest opening in a reducing fitting governs the tolerances to be applied to all openings. These tolerances do not apply to return bends and caps.

7 THREADING

7.1 Types of Threads

All fittings shall be threaded according to ASME B1.20.l and shall have taper threads, except wrought couplings (Tables 8 and 1-8) and wrought caps (Tables 9 and 1-9) in NPS 1/8, 14, and 8, which may have straight threads.

7.2 Tolerances

Variations in taper threading shall be limited to one turn large or one turn small from the gaging face on ring and gaging notch on plug when using working gages. The variations in straight threading shall be limited to one and one-half turns large or small from the gaging notch on plug when using a taper pipe thread working gage. The reference point for gaging internal fittings threads depends upon the chamfer diameter. When the internal chamfer diameter exceeds the major diameter of the internal thread, the reference point is the last thread scratch on the chamfer cone. When the internal chamfer diameter does not exceed the major diameter of the internal thread, the reference point is the end of the fitting. (See Fig. 2.)

7.3 Countersink or Chamfer

For the purpose of easier entrance in making a joint and for protection of the thread, all internal threads shall be countersunk a distance of not less than one-half the pitch of the thread at an angle of approximately 45 deg with the axis of the thread; all external threads shall be chamfered at an angle of 30 deg to 45 deg with the axis. Countersinking and chamfering shall be concentric with the threads.

7.4 Thread Length.