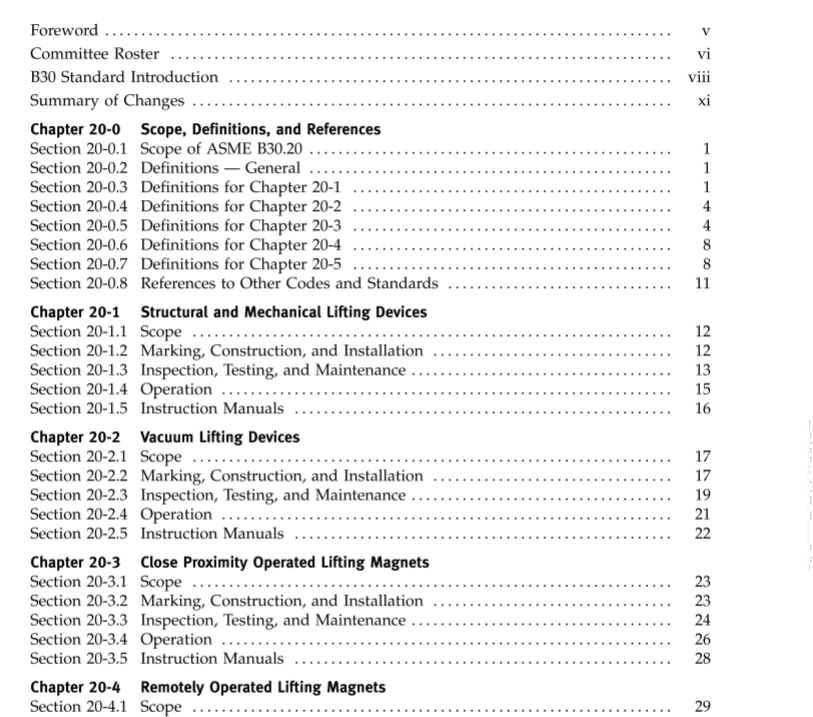

ASME B30.20-2006 pdf download

ASME B30.20-2006 pdf download.Below-the-Hook Lifting Devices.

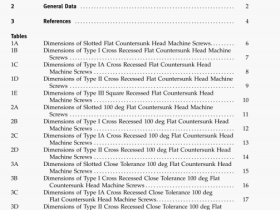

ingot turnover grab: a manipulating lifter [Fig. 4, sketch (e)].

latch: a device for holding a lifter in the open or closed position.

latch, automatic: a sequencing latch mechanism operated by lifter motion.

lifting beam (spreader beam): a load-supporting lifter [see Fig. 5, sketch (a)].

lock bar sheet lifter: a supporting lifter [see Fig. 5, sketch (j)J.

manipulating lifter: a lifter that rotates the load about one or more axes during the lifting process (see Fig. 4).

mechanical lifting device: a mechanism composed of two or more rigid parts which move with respect to each other for attaching a load to a hoisting device.

service, heavy: that service which involves operation within the rated load limit that exceeds normal service.

service, normal: that distributed service which involves operation with various weights within the rated load limit, or uniform loads less than 65% of rated load.

service, severe: that service which involves normal or heavy service with abnormal operating conditions.

structural lifting device: a lifter consisting of an assembly of rigid parts designed to hold and attach a load to a hoisting device.

supporting lifter: a lifter that carries the load on rigid projection(s) or bearing surface(s) (see Fig. 5).

SECTION 20-0.4: DEFiNITIONS FOR CHAPTER 20-2

breakaway force: the external force that is required to separate the vacuum pad or vacuum lifting device from the load when applied perpendicular to the attachment surface.

four-pad powered vacuum lifter: see Fig. 6, sketch (d). four-pad powered vacuum lifter manipulator: see Fig. 6, sketch (e).

high-temperature surface: a condition where the surface to which the vacuum pad (or pads) is attached is above

250°F (120°C).

horizontal lift: a condition where the surface to which the vacuum pad (or pads) is attached is in a horizontal plane.

low-temperature service: a condition where the surface to which the vacuum pad (or pads) is attached is below

0°F (—18°C).

multiple-pad mechanical vacuum lifter: see Fig. 6, sketch (c). nonporous material: a material that is not permeable by fluid.

peel off a prying action that takes place when deflection of an overhanging load exceeds the compensating ability of the vacuum pad or vacuum lifting device, resulting in loss of load.

porous material: a material that is permeable by fluid. scaling ring: that part of the vacuum pad which forms the seal of the vacuum chamber between the vacuum pad body or vacuum lifting device and the attached material.

service, heavy: that service which involves operation within the rated load limit that exceeds normal service.

service, normal: that distributed service which involves operation with various weights within the rated load limit, or uniform loads less than 65% of rated load.

service, severe: that service which involves normal or heavy service with abnormal operating conditions.

shear breakaway force: the external force that is required to separate or slide the vacuum pad or vacuum lifting device on the load when the force is applied parallel to the attached load surface.

single-pod mechanical vacuum lifter: see Fig. 6, sketch (b). two-pod mechanical vacuum lfter: see Fig. 6, sketch (a).

vacuum: pressure less than ambient atmospheric pressure.

vacuum lifter: a below-the-hook lifting device for lifting and transporting loads in a fixed attitude using a holding force by means of vacuum (see Fig. 6).

vacuum manipulator: a vacuum lifter capable of repositioning the load while suspended.

vacuum pad: a device that applies a holding force on the load by means of vacuum.

vacuum reservoir: the evacuated portion of the vacuum system whose function is to compensate for leakage into the vacuum system or to provide a vacuum reserve in the event of vacuum generator failure.

vertical kit: a condition where the surface to which a vacuum pad is attached is in a vertical plane.

SECTION 20-0.5: DEFINITIONS FOR CHAPTER 20-3

battery sz,stenz (backup): batteries used to guard against inadvertent load release due to the loss of primary power to the magnet system.

cold current: that current drawn by the lifting magnet when its coil is at 68°F (20°C) and at rated voltage.