ASME A112.19.13-2001 pdf download

ASME A112.19.13-2001 pdf download.ELECTROHYDRAULIC WATER CLOSETS.

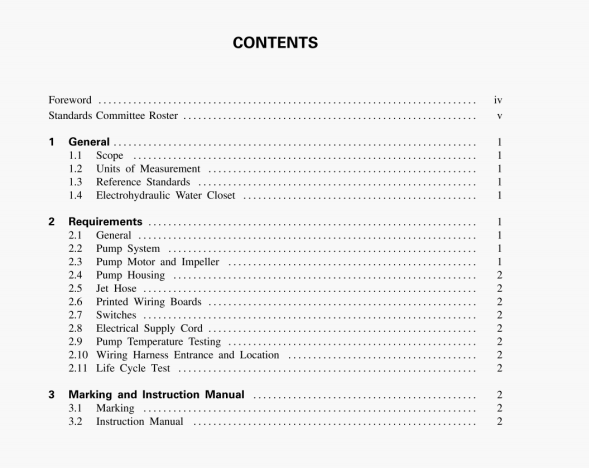

1.4 Electrohydraulic Water Closet

An clcctmhydraulic water closet is a siphonic or wash.down water closet as described in ASME A1l2.l9.2M with a nenmechanical trap seal. The water closct incorporates clectncal motors). pump(si. and cornrnlkrs to facilitate the flushing action.

In this Standard, the term waler ck?.wt means an electrohydraulic staler closet unless otherwise indicated.

2 REQUIREMENTS

2.1 General

2.1.1 Water Closet. The water closet shall conform to the requireinent contained in ASME Al I2.19.2M or ANSI 1124.4. as appropriate, it shall also meet the requirements of ASME A 112.19,6.

2.1.2 Electronic and Electrical Components. The electronic and electrical components utilized in the water closet shull comply with the appropriate underwriters Laboratories (UI) standard or portions thereof as may he indicated in this Standard.

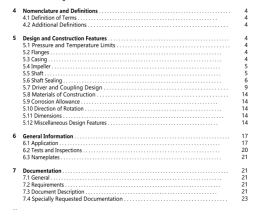

2.2 Pump System

The pump systems of an clectrohydraulic water closet shall be rested as a water pump in accordance with LIL 778. The applicable sections of UI 778 for compliance are:

fa) Construction. sections I through X and 10 through 28;

fb) Perlormance. sections 29 through 35 and 37 through 47;

(ci Manufacturing and Production Tests. sections 49 and 50:

fd) Rating. section 51:

fr) Markings. sections 48. 52. and 53;

(j) Instruction, sections 54 and 55.

2.3 Pump Motor and Impeller

The pump motor to the pump impeller coupling shall

be nonmechanical and seamless. To minimize electrical hazards, the design shall a completely sealed chamber fur the motor and electronics without the use of seals or O-.ings.

2.4 Pump Housing

klectnc motors 0f pump enclosures shall comply with UL 746C and be plastic rated 94-5V or better as specilied in UL 746C.

2.5 Jet Hose

The pump jet hose, if provided, shall withstand a pressure of 25 ± 1 psi (172 ± 69 kPal for 64) mm.

2.6 Printed Wiring Boards

Wiring boards shall comply with UL 244A-1994. sectiotts 14.1 and 14.2. and UL 796.

2.7 Switches

Switches shall be located in class 2 cittuits only.

NOTE A dim 2 rknth es a circu$ with an open petenual of no nwire ilani 30 V mis (42,2 V peaki supphed b either an inhetenti> twiuicd cbse 2 imair.fonner in a iran4t’rrner arni flied ‘inpeitne lint ipthcr conipi> with all the rnjuaremtnt. lot inhennit tanned ctasa 2 nnsilomwrs in LI 1555.

2.6 ElectrIcal Supply Cord

hlcctncal supply cords shall be provided with 3 ft (0.9 m) minimum. 6 ft (l.X m) masimum of permanently attached cord and an attachment plug for connection to the branch-circuit supply. The cord shall conform to UI. 62 or UI. SIT, it shall be marked “Water Resistanf and include an equipment•grounding conductor. Where the electncal supply cord exils the lixture. the surface shall be smooth, with rounded surfaces or provided with a grommet Seals and gaskets shall conform to UL 157.

2.9 Pump Temperature Testing

The pump shall be tested as desenhed in para. 2.2(b), seCtiou 34 of tJL 77k, at the maximum duly cycle the pump will allow.

2.10 Wiring Harness Entrance and Location

The wiring harness and electrical controls nut enclosed in the pump housing shall he lucated above the flood level rim of the tank or reservoir and above the drains or uveiflows.

2.11 Ufe Cycle Test

The electrical components and pump shall pass a 75.000 life cycle lest. The lest shall he performed on the waler closet at the maximum cycle rate the electronic controls will allow, Upon completion of the life cycle test, the average volume per flush shall not vary more than 0.15 gal (0.57 L) or l0’’. whichever is greater.

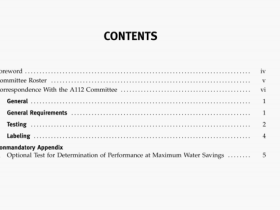

3 MARKING AND INSTRUCTiON MANUAL

3.1 Marking

3.1.1 Water Closet. The waler closet shall he legibly marked as specified in ASME Al l2.19.2M and other standards rclircnccl in this Standard 15cc pant. 1.3).

3.1.2 Pump. The pump shall have the following markings visible on it in its normal operating position and a second label visible on the exterior ol the water closet or cord stating:

3.2 Instruction Manual

An instruction manual shall be provided that includes instnk-tirms fur routine mniuntenunee and operation.