ASME B16.11-2016 pdf download

ASME B16.11-2016 pdf download.Forged Fittings,Socket-Weldingand Threaded.

(c) Product Conformance. Fittings covered under para. 1.1.1 shall be marked with either the ASTM Fittings Specification material identification (e.g., WP 9 or the symbol “816 “to denote conformance to this Standard. Fittings covered under para. 1.1.2 shall be marked with a supplementary suffix as follows:

(1) For ASTM A234, A403, A420, and A815, suffix the material grade with “S58 (see ASTM A960 Supplementary Requirement S58).

(2) For ASTM Fitting Specification B366. suffix the material grade with ‘SPLD.

(3) For all ASTM Forging Specifications, suffix 1316” with SPLD.N

(d) Class Designation. 2000, 3000, 6000, or 9000. as applicable. Alternatively, the designation 2M, 3M, 6M, or 9M, as applicable, may be used where M stands for 1000.

(e) Size. The nominal pipe size related to the end connections.

4.1.2 Omission of Markings. Where size and shape of fittings do not permit all of the above markings, they may be omitted in the reverse order given above.

5 MATERIAL

5.1 Standard Materials

Fittings shall be made of materials consisting of forgings, bar, seamless pipe, or seamless tubular products. These materials shall conform to the requirements for the WP seamless construction materials of ASTM Fitting Specifications A234, A403, A420. A815, or B366 or ASTM Forging Specifications A105, A182, A350, B462, or B564. Tees, elbows, and crosses shall not be machined directly from bar stock.

6 DIMENSIONS

6.1 General

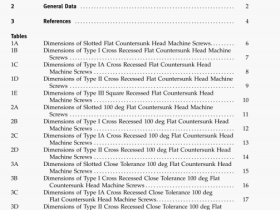

Unless otherwise noted, the dimensions without tolerances for socket-welding fittings given in Tables 1,2, 11, and 1-2 and the dimensions without tolerances for threaded fittings given in Tables 3 through 6 and Tables 1-3 through 1-6 are nominal values and subject to the designated manufacturing tolerances.

6.2 Socket Fittings

6.2.1 Body Wall Thickness. The body wall thickness o socket-welding fittings shall be equal to or greater than the values, G, shown in Tables I and 1-1.

6.2.2 Socket Wall Thickness. The socket wall average thickness and minimum thickness shall not be less than the corresponding values, C, shown in Tables 1, 2, 1-1, and

6.2.3 Socket Position. The fixed position for the bottom of the socket with reference to the centerline of the socket-welding fitting shall be maintained as required by the dimension. A, of Tables 1 and I-I. For reducing fittings, see para. 6.5.

6.2.4 Socket Depth. The socket depth shall not be less than the minimum values,), shown in Tables 1, 2, 1-1, and

6.2.5 Socket Bore. The inside surface of the socket bore shall present a good workmanlike finish that is free of burrs.

6.2.6 Perpendicularity. The end flats of socket- welding fittings shall be at right angles to the socket axis.

6.2.7 Width. The forging radius shall not reduce the width of the flat welding surface to less than the value shown in Figure 2.

6.3 Threaded Fittings

6.3.1 Wall Thickness. The body or end wall thickness of threaded fittings shall be equal to or greater than the minimum values, G, as shown in Tables 3 through 5 or Tables 1-3 through 1-5.

6.3.2 Internal Threading. All fittings with internal threads shall be threaded with American National Standard Taper Pipe Threads (ASME B1.20.1). Variations in threading shall be limited to one turn large or one turn small from the gaging notch when using working gages. The reference point for gaging is the starting end of the fitting, provided the chamfer does not exceed the major diameter of the internal thread. When a chamfer on the internal thread exceeds this limit, the reference point becomes the last thread scratch on the chamfer cone.

6.3.3 External Threads. All externally threaded fittings shall be threaded with American National Standard Taper Pipe Threads (ASME B 1.20.1), and the variation in threading shall be limited to one turn large or one turn small from the gage face of ring when using working gages. The reference point for gaging is the end of the thread, provided the chamfer is not smaller than the minor diameter of the external thread. When a chamfer on the external thread exceeds this limit, the reference point becomes the last thread scratch on the chamfer cone.